Projects

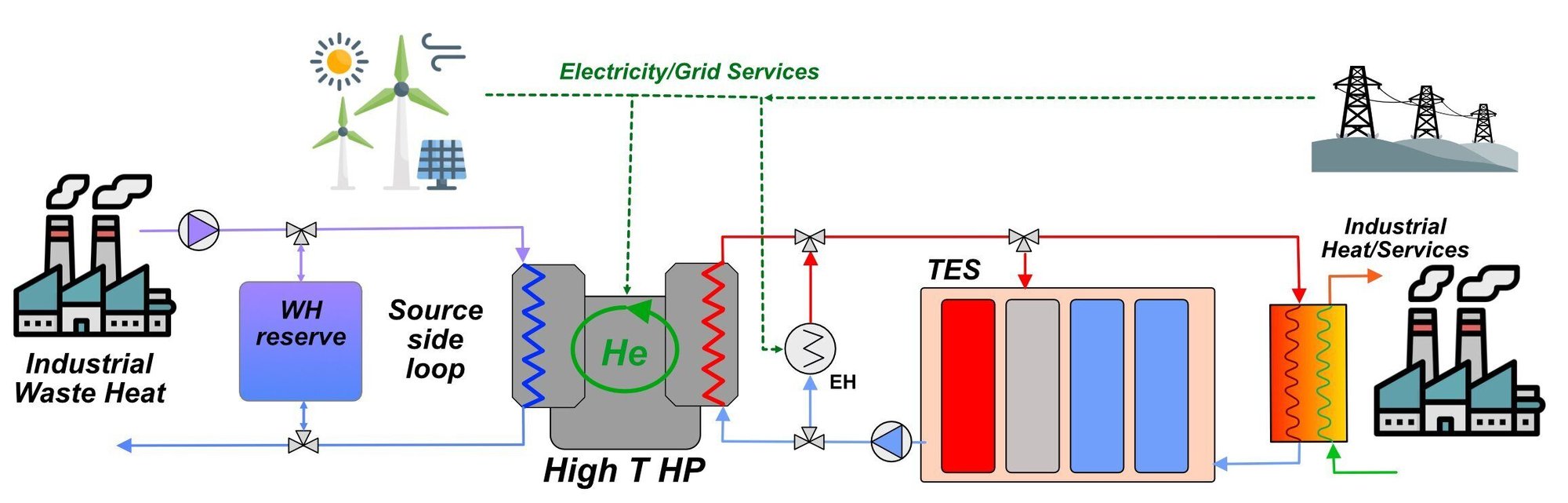

I-UPS (Innovative High Temperature Heat Pump for Flexible Industrial Systems) develops a first-of-its-kind, cost-effective high-temperature industrial heat pump and thermal storage system, aiming for efficient heat decarbonization.

The project, a collaboration among SMEs, research institutions, and industrial partners, focuses on integrating this innovative heat pump into flexible energy systems. It targets medium-temperature applications (~400°C) in an industrial setting. By optimising key components and leveraging advanced technologies, I-UPS enhances system flexibility and sustainability. This initiative helps position Europe as a leader in industrial heat pump solutions, promoting energy efficiency, waste heat recovery, and reduced carbon emissions in the industrial sector.

The industrial sector, a significant contributor to the global economy, producing about one-quarter of the global gross product, it is also a major source of CO2 emissions.

Almost 25% of the overall global energy demand is for heating in the industrial sector, which is predominantly generated by fossil fuels, leading to about 40% of global CO2 emissions. Tackling this environmental challenge requires innovative solutions that reduce the heating sector's environmental impact while maximising energy systems' integration and flexibility.

The I-UPS project sets out to revolutionise industrial heating by developing and validating a first-of-a-kind (FOAK), cost-effective, and reliable high-temperature industrial heat pump, coupled with thermal energy storage.

This innovative technology aims to deliver decarbonized heat in the form of steam, up to 400°C.

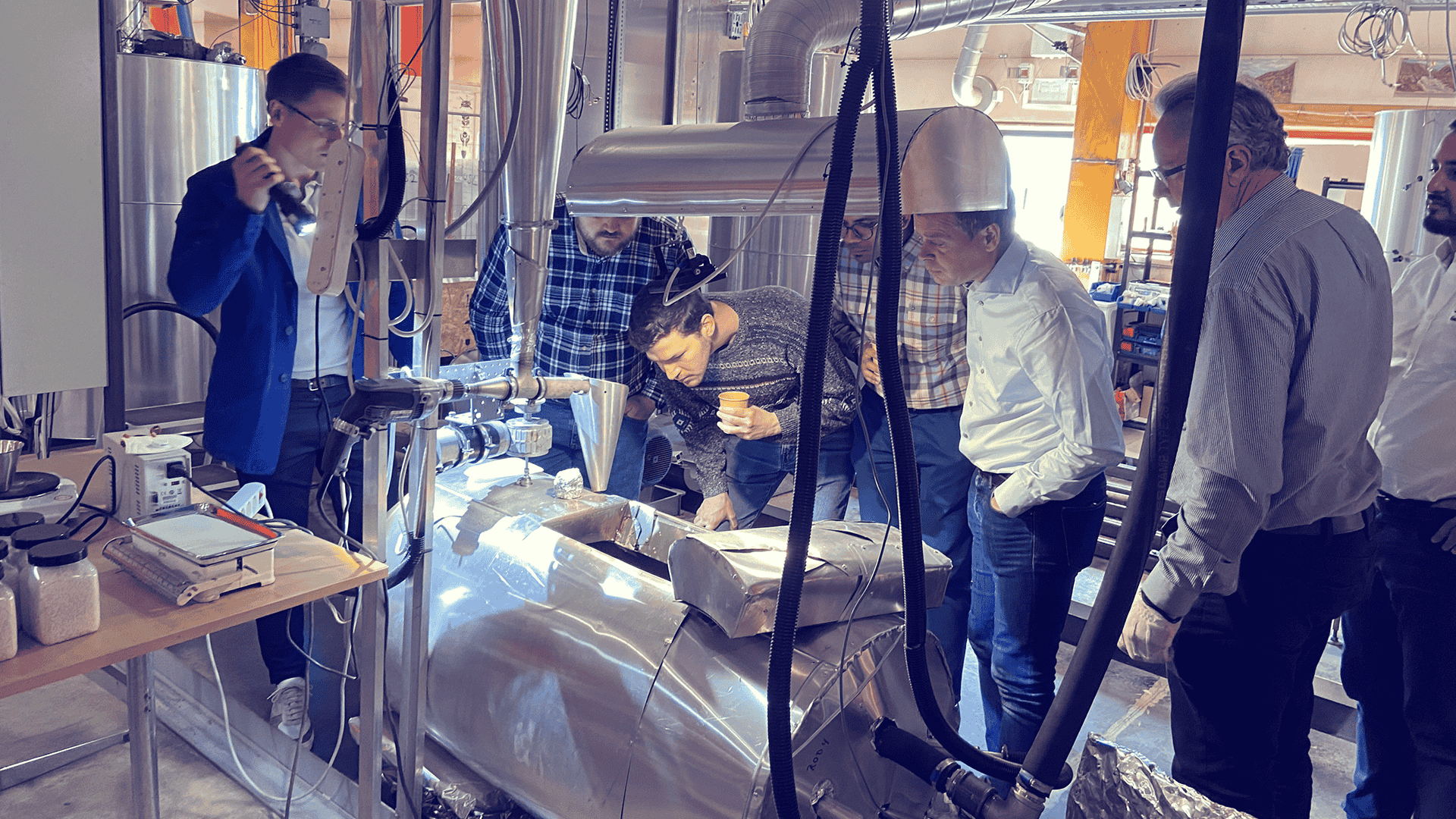

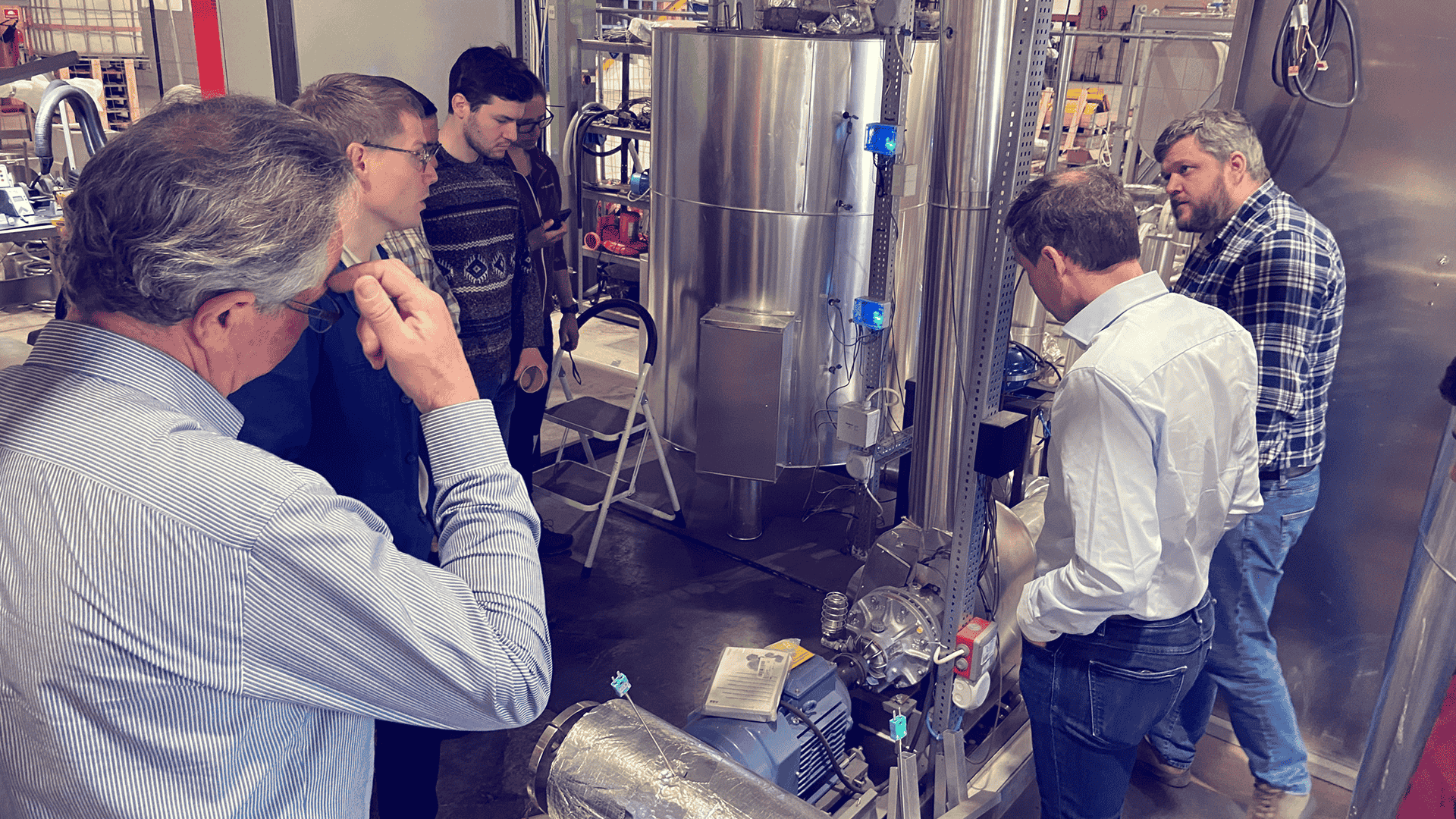

In this context, I-UPS aims to validate up to TRL 5, a pioneering high-temperature heat pump (HTHP) based on Stirling engine technology. This HTHP uses a non-toxic, inert working fluid with zero ozone depletion potential (ODP) and zero global warming potential (GWP). This technology stands out because no other commercial alternatives can achieve such high heat delivery temperatures at efficiencies greater than 100%. The I-UPS project focuses on key subcomponents such as static and dynamic sealing solutions and compact heat exchangers.

I-UPS will integrate the developed high-temperature heat pump into flexible energy storage systems, including Kyoto’s molten salts-based thermal energy storage (TES), for on-demand decarbonized industrial heat powered by renewable electricity.

This integration is achieved through the design and development of optimised compact heat exchangers (pressurised gas to molten salts), ensuring reliable high-temperature operation and fast ‘plug-and-play’ installation. The proposed integrated heat pump configuration offers higher modularity, flexibility, and efficiency for heating decarbonization, leveraging waste heat recovery and contributing to the circularity of the industrial sector.

Technological Challenges in Decarbonizing Industrial Heat

Reducing CO2 emissions from the industrial sector is a critical challenge due to its significant contribution to global greenhouse gas emissions. The industrial sector accounts for approximately 22% of the world's energy demand, largely produced by fossil fuels, resulting in about 40% of global CO2 emissions. This sector's heavy reliance on high-temperature heat for processes exacerbates the issue, making it essential to develop innovative, sustainable solutions to decarbonize industrial heat, improve energy efficiency, and reduce environmental impact.

Development of a Reliable, Modular Heat Pump

The key aim for I-UPS is to help Enerin develop their HoegTemp(R) High Temperature Heat Pump into a reliable, commercialised unit, achieving an outlet temperature of 400°C and utilising waste heat up to 80C. The heat pump offers minimal environmental impact, using inert, zero GWP, and zero ODP fluids.

Heat Exchanger Design

KTH and Enerin shall combine to develop a heat exchanger capable of transferring heat from the HTHP working fluid, to molten salts. This also involves developing an efficient sealing method.

Dynamic Control

This is facilitated by advanced control systems, ensuring maximum flexibility, high response demand capabilities with quick load ramping, and optimal energy system integration providing flexibility to sector coupling. This targeted development could help reduce strain on the power network and improve its resilience, addressing key challenges in industrial electrification.

Impact Assessment

I-UPS will develop tools aimed to calculate and optimise the impact of the proposed heat pump and energy storage system integration throughout its lifecycle. The assessment also aims to maximise the techno-economic potential of the solution, validating its extensive benefits compared to commercial solutions.

Aims of the I-UPS project (4 USPs)

Accelerate technology to TRL5

The project aims to progress the high-temperature heat pump (HTHP) coupled with TES to TRL5, This will accelerate future development to take the concept to a fully commercial unit.

Increase Performance

I-UPS shall develop new architecture for the stirling based HTHP, develop seals and heat exchangers and investigate additive manufacturing techniques to fully optimise the performance of the system.

Enhance Supply Security

By increasing the security and resilience of the heating sector and power grid, the project ensures a stable and reliable industrial heat supply.

Cut Heat Supply Costs

The project reduces industrial heat supply costs, targeting a levelized cost of heat (LCoH) of ≤25 €/MWh, making it more accessible to industry.

Key Objectives of the I-UPS Project

Develop 400°C Heat Pump

Create a modular, cost-effective industrial heat pump delivering decarbonized heat up to 400°C, minimising environmental impact with inert, zero GWP, and zero ODP fluids.

Optimise Seals & Exchangers

Develop and optimise critical components like static and dynamic seals and heat exchangers to improve overall performance of the system.

Integrate Energy Systems

Seamlessly integrate the heat pump with molten salts-based thermal energy storage, ensuring reliable high-temperature operation and fast ‘plug-and-play’ installation.

Reduce Environmental Impact

Use lifecycle tools and models to minimise socio-environmental impact, ensuring a cradle-to-grave approach and maximising circularity and sustainability.

Promote Industrial Decarbonization

Support industrial heating decarbonization by promoting waste heat recovery, reducing fossil fuel reliance, and boosting market adoption of high-temperature heat pump technologies.

The Consortium

The I-UPS project brings together a consortium of technology developers in thermal energy.. Key partners include KYOTO Group, ENERIN, KTH Royal Institute of Technology, RPOW and UNIGE. These partners collectively contribute their expertise in energy systems, advanced manufacturing, and sustainable technologies to ensure the success of the project.

KYOTO Group AS specialises in thermal energy storage solutions, offering critical insights into integrating high-temperature heat pumps with storage systems. ENERIN brings extensive experience in developing and optimising high-temperature heat pumps based on Stirling cycles. KTH Royal Institute of Technology provides advanced research capabilities and innovative methodologies for component design and system optimization. RPOW provides consultancy and engineering services to the industry, possessing extensive experience in the design of equipment for CSP, solar, and other renewable sectors. UNIGE (University of Geneva) adds expertise in dynamic modelling and control systems, ensuring the efficient and flexible operation of the integrated energy system.

This collaborative effort highlights the importance of interdisciplinary cooperation in advancing sustainable industrial solutions. The combined strengths of these organisations ensure that the I-UPS project not only achieves its technical goals but also sets a benchmark for future innovations in industrial heat decarbonization.

Do you want to know more?

Get in touch with our I-UPS experts

Silvia Trevisian

Researcher, KTH

Focused on developing cost-effective Thermal Energy Storage (TES) solutions to enhance renewable energy integration, Sylvia’s research spans component development, prototyping, and system performance assessments. Her work on high-temperature TES systems aims to decarbonize energy-intensive industries and promote electrification through innovations like heat pumps and electric heaters. Sylvia's efforts contribute to achieving Sustainable Development Goals and supporting more sustainable industries and communities.

Get in touch via e-mail trevisan@kth.se

James Brown

Head of Development, KYOTO Group AS

An Engineer with 17 years of experience, has been with Kyoto Group since early 2022. Specializing in electric heaters for thermal energy storage, he has spent 15 years in R&D, holds a growing patent portfolio. Passionate about reducing carbon emissions, James works closely with industry leaders and teams to integrate cutting-edge technologies that support Kyoto Group’s mission to provide clean energy storage solutions. He is pursuing a PhD focused on optimizing electric heaters for thermal energy storage.

Get in touch via e-mail james.brown@kyotogroup.no

Newsletter

Join our mailing list to receive the latest I-UPS updates